DevWing

Foam by the devCad Team

|

DevWing Foam, the innovative application to cut foam wings with a

CNC hotwire machine

-

Using DevWing Foam you can draw and cut in a very simple way

a foam wing using a 4 axis foam cutting CNC

-

The Project Wizard will drive you to draw and cut the foam wing using a

step by step approach. No Cad skills are required!

-

Every half wing will be defined by one or more Panels. You will split the half

wing in more panels if/when some geometry setting changes (airfoil, dihedral,

washout and so on).

Every Panel will be defined by one or more Blocks. You will split a

Panel in more blocks when it's too long for your CNC machine or when the plan

form of the panel is not trapezoidal, but, for example with curved leading

and/or trailings edge.

-

After creating the Project, you can use it to create a Cutting Project,

where you specify with a step by step approach all the settings required to

create the right cutting files

-

You can also draw and cut by a 3 axis CNC milling machine other

wooden parts like side ribs, nose checking templates, shaped spars and so

on.

-

Creating a foam wing with a complex wing plan, different airfoils and a lot of

available elements is no more a problem. In just a few minutes you can have

your wing geometry defined, you can check it in 3D and start to work on one or

more Cutting projects.

-

By a 3D preview you can check every step of the creation of the wing,

and go forth and back among the project wizard panels to retouch

them.

-

You can add to the Wing Project many internal elements, like spars, leading and

trailing edges, lightening holes and aileron/flap slots. You can specify a

different cutting startegy for each element, so that the cut could

not interfere the final wing core and the outer shells.

-

The Cutting Project lets you to add in a single cutting job more wing parts

(called blocks in devWing Foam).

-

A separate shaping side cutting job will also created to shape the Foam block

at root and tip sides. If you rearrange for example dihedral values during the

cut, the root/tip side will be cut with the right angle to assemble then them.

-

You can then export the foam cutting files selecting by many available file

formats like GCcode/NC, Cut files for GMFC, DXF, DAT, Hpgl/Plt.

-

You can also preview the cutting job using the supplied 3D cutting emulator, so

that you could verify all the settings before running the real cut.

-

To download devWing Foam see the Download

section of the web site.

-

To get a license see the Prices section of the web

site.

|

|

|

A

fast preview of devWing Foam features: the Wing Project A

fast preview of devWing Foam features: the Wing Project

|

Wing plan drawing

You can draw a complex multipanel wing plan, also using a picture or DXF file

as a reference backgrond

|

|

|

Blocks definition

If a Panel is too long for your CNC foam cutting machine or you have curved

Leading/Triling edges, you can create multiple Blocks, with special

functions to speed up this process

|

|

|

|

|

Sheetings

You can set here the optional sheetings

|

|

|

|

|

|

|

|

|

|

|

Lightening holes

Using this page you can add manually or automatically lightening holes.

|

|

|

|

|

|

the

Cutting Project the

Cutting Project

|

Select the Block

to cut

Once you created a Wing Project you can create one or more Cutting Project. The

first step is selecting the Blocks to cut from the actual Wing Project

|

|

|

|

|

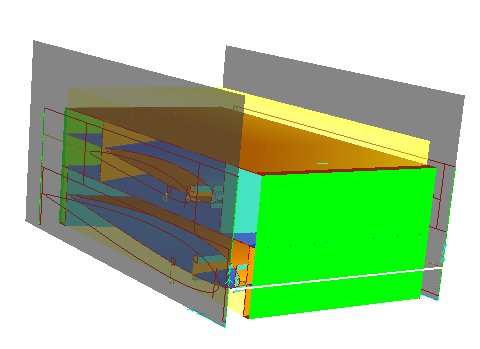

Set

cutting order and Foam Block size

In the third step of the Cutting Project you will specify the cutting

order of the Blocks, the Foam block size and the placement of each block inside

the Foam

|

|

|

|

|

|

|

|

|